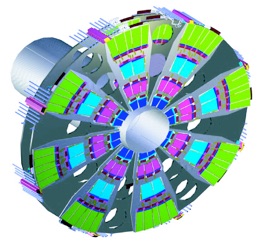

The forward part of the CMS tracker is made of nine carbon fiber disks covered with up to

seven rings of silicon strip detectors. For reasons of modularity the detector modules

together with all necessary services (cooling, power, readout) are mounted on sub

elements (‘‘petals’’), which are in turn mounted on the carbon fiber disks.

This concept of a modular support structure for the tracker endcaps has been developed by our group. The CF petal mechanics including all Al-inserts and the titanium cooling pipes have been assembled for 288 petals at the RWTH Aachen. In the following production step the interconnection boards, which provide all electrical connections for the Si- Detector Modules have been mounted in Aachen. This production was completed in January 2006.

The pre-assembled petals were than equipped with opto-hybrids at the Uni. Hamburg. In six different production sides, RWTH Aachen, Uni. Brussels, Uni. Karlsruhe, Uni. Louvain, Uni. Lyon and Uni. Strasbourg Si-Detector modules were than mounted and the petals were tested at -20 degrees Celsius.

Fully qualified petals were than shipped back to our institute for integration into TEC+ and to CERN for integration into TEC-.

Photos from the Petal construction in Aachen

Bibliography:

-

(1)Brauer, R. and others, „Design and test beam performance of substructures of the CMS tracker end caps“, cms-note-2005-025